Fully Automatic Horizontal Baler

Our fully automatic horizontal balers are an automated version of our horizontal balers, able to process high volumes of recyclable materials such as paper, cardboard and plastics, ideal for companies with a large amount of daily waste to handle.

Materials are pressed into stable, high-density bales by our fully automatic balers, which are easy and safe to stack, requiring less storage space. The length and weight of bales is selectable, with bales being tied automatically when the selected length is reached.

Our fully automatic horizontal balers are CE marked and designed with customer requirements in mind, making your waste management a simple and cost efficient process.

Enerpat Direct supply a full range of fully automatic horizontal balers to handle all the standard materials such as cardboard, soft plastics (shrink-wrap, plastic sheeting), PET bottles as well as hard plastics, aluminium and steel cans and even difficult materials such as RDF (Refuse Derived Fuel).

Fully automatic balers are required when a throughput over 2 tonnes per hour is needed. Tying-off of bales is carried out automatically.

Enerpat’s fully automatic horizontal baler, ranging from 20 tons to 200 tons pressure force, has a processing power of up to 25 tons per hour. It is perfect for recyclers handling large daily amount of soft waste such as cardboard/OCC (popular as cardboard baler or OCC baler), paper, plastic film, natural fiber, textile waste, soft plastic package, etc. This fully automatic baling machine is also our flagship line of horizontal open end baling machines. It combines advanced computer controlled operations with reliable hydraulics and seamless heavy duty frame construction. Troubleshooting of this automatic line baling machine can be controlled from the Mitsubishi PLC, and with Remote Control on PLC system, we are able to extend our technical assistance no matter where the machines are. All of these advanced features do not get in the way of operation – this is very simple baling machine to run.

Bale weight and length of this auto-tie horizontal baler can be programmed and controlled through a easy-to-use touch screen panel according to your specific transportation arrangement, making it ideal to maximize your container loading. For example, HBA120-110130 model horizontal baling press, is able to produce super dense rectangular bale up to 1200kg each, with bale size up to 2300mm x 1100mm x 1300mm. You can load up to 26 tons of OCC bales produced by this machine into a 40’HQ container without the need to turn the bales around from one side to another. Also rectangular bale is much easier for storage and transportation compared to round bale.

HBA100-110110 Official Photo

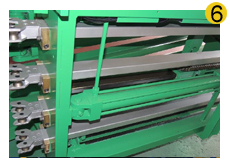

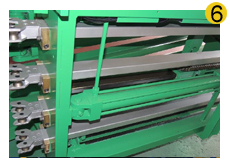

Conveyor

with feeding conveyor to fill the baler evenly and continuously

we install conveyor for all our auto horizontal baler

the thickness of the steel plate for the conveyor at least 3mm

all conveyors are made by enerpat

Special Press Ram

Control Panel

Independent Cooling System

we supply 3 hydraulic system cooling choice

(1) Industrial cooling machine,like our Home Air Conditioning,we can set one ideal temperature for the hydraulic system,once the temperature exceed the setted data,the machine will Alarm for warnings.which system also support 24 hours running.

(2) Electrical cooling fun

(3) Water cooling machine

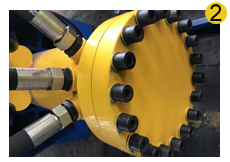

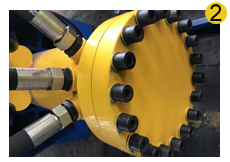

Tying Bale System 1

Tying Bale System 2

Top Press Ram

More Models,Your Choice

Model

| Bale Size

(mm)

(WxHxL)

| Bale Weight

(Cardboard)

(kg)

| Motor Power

(kw)

| Output

(t/h)

| Machine Size

(m)

(LxWxH)

|

| HBA-40-7272 | 720x720x500~1500 | 200~350 | 22+1.5+2.2 | 1-3 | 6.3x3.0x2.1 |

| HBA-60-7585 | 750x850x500~1500 | 300~450 | 30+1.5+2.2 | 2-4 | 6.8x3.0x2.15 |

| HBA-80-11075 | 1100x750x500~1500 | 400~600 | 37+1.5+2.2 | 4-8 | 8.0x3.7x3.8 |

| HBA-100-11075 | 1100x750x500~1800 | 600~800 | 45+1.5+2.2 | 6-9 | 10x3.7x3.8 |

| HBA-100-110110 | 1100x1100x500~1800 | 800~1000 | 45+1.5+2.2 | 7-12 | 10x3.7x4.6 |

| HBA-120-110130 | 1100x1300x500~1800 | 900~1100 | 55+1.5+2.2 | 9-13 | 11x3.7x4.9 |

| HBA-150-110130 | 1100x1300x500~1800 | 1100~1300 | 45x2+1.5+2.2 | 14-18 | 11x3.7x4.9 |

| HBA-180-110130 | 1100x1300x500~1800 | 1200~1400 | 55x2+1.5+2.2 | 17-25 | 11.6x3.7x5.5 |

| HBA-200-110130 | 1100x1300x500~1800 | 1400~1600 | 55x2+1.5+2.2 | 17-25 | 11.6x3.7x5.5 |