Ecnomic Single Shaft Shredder For Trash Bin

Why Today one needs a Trash Bin Shredder?

Trash bin single shaft shredder can be office paper shredder which looks like a trash bin. Industrial trash bin shredder can be an industrial heavy duty shredder which is used to shred plastic trash bins.

With our ever-increasing need for data security and safely discarding this data at home and at work, the elimination of our personal and professional information requires the need of a trash bin shredder.

Business plans, account statements, invoices – day to day’s important information is passed through our hands. But these often end up in the paper basket, even other data medias such as CD’s and credit cards are often simply thrown into the garbage. From our Garbage, it becomes convenient for data thieves to steal information about our personal and professional life. It’s easy to get rid of potential data spills right from the start – destroy your document and data before you discard them.

With Trash bin single shaft shredder one can easily dispose of:

How to choose a right Trash bin single shaft shredder in your office or home? Choosing the right trash bin shredder requires 3 crucial factors:

There are two types of Trash bin single shaft shredder: those that perform a strip cut and devices that perform a cross cut. In strip cutting, the paper sides are cut into small strips. These can be put together in principle and with a lot of effort again, which however with non-explosive papers probably no one will make. For the domestic use, such a device is sufficient. The cross-section cuts horizontally and vertically, leaving small rectangles. To reassemble this is almost impossible for a layman. A device with the cross section is thus safer, but louder and slower because a device with a strip cut can cut more pages at the same time. In addition, the device with cross-cut is usually more expensive as compared to strip cutter. There are also the Particle-cut shredders, they provide the highest level of safety. They shred paper into confetti-sized particles. They are 6 times faster than standard commercial paper shredders.

2. Application area

For use at home, a small Trash bin single shaft shredder with a small basket or the one which will fit on the top of your trash can serve the purpose.

But for offices, where one requires professional destruction after use, one requires shredder for multiple users, larger paper baskets, and more powerful engine.

3. Safety level

If the required security level is high, one can choose to shred into smaller shreds, hence protecting information further.

Such small trash bin shredders are the need of the hour today. With increasing privacy breaches, it is essential to destroy what you throw away. As they come in various shapes and sizes, it becomes highly convenient to own one. As they are available at low prices, they are not only affordable but also with its high usability it is a must for every home and office.

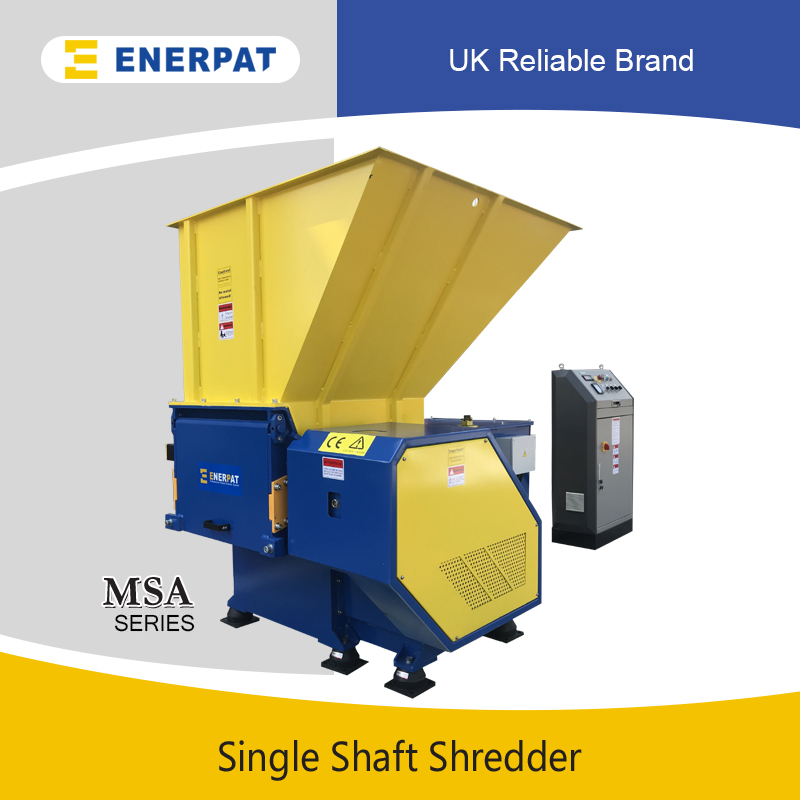

Industrial trash bin shredder is much bigger in size and it is designed to shred plastic trash bins waste. Both single shaft shredder and double shaft shredder can be available for trash bin shredding purpose. You just need to tell professional shredder manufacturer your plastic trash bin size, required output and final product size. They will tailor your needs to a specific trash bin shredding machine.

Official Photos

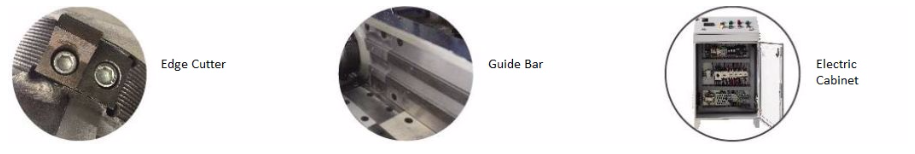

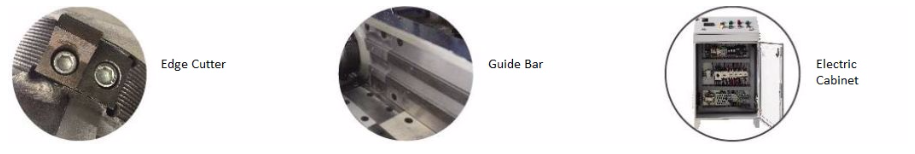

Rotor

Chevron rotor design

Rotor knives manufactured from special heat treated DC53 steel. They can be rotated and used on four edges before replacement

Long life fixed blades that can be adjusted to maintain cutter clearance

Wear resistant coating. Optional for applications involving abrasive material such as fibre glass

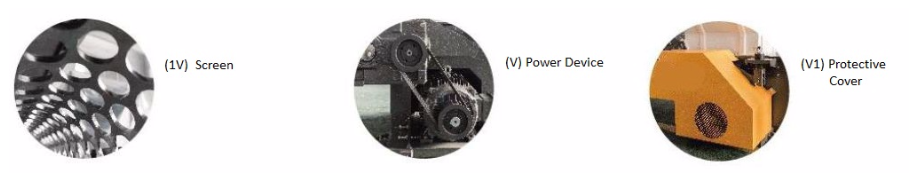

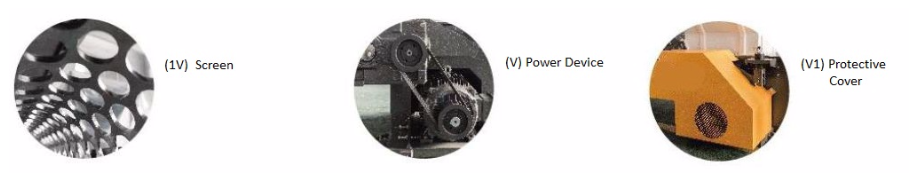

Screen Basket

Quick change screens for accurate particle size control (sizes 12-100mm)

Safety limit switch fitted to screen access door to prevent machine operation whilst access door is open

Cylinders access door opener mounted on V800-V1500 series for easy opening and access

Star screen is available as an option for thin and/or flexible material such as film

Bearings

Oversized, high quality spherical shaft bearings are isoloated from the cutting chamber to prevent product migrations through the grease seals

Bearing housing integral machined to ensure the longevity of the bearings

Rotor water cooling. Optional water cooling through the bearing housing to the rotor

Ram

Segmented shredding chamber floor with brass guides

Machined, one-piece segmented floor

Advanced adjustable sealing system for the pushing unit

Fines discharge chute to the collect the fines during shredding and to protect the hydraulic power pack

Drives

Electric drive motors configured for Star/Delta starting. Fluid coupling mounted on V1200 and V1500

Heavy duty reduction gearbox mounted directed onto the rotor shaft

Shock absorbing gearbox mountng arrangement to reduce stress on drive components

Hydraulic System

Twin speed hydraulics, faster speed for backwards to maximise the shredding throughput

Integrated oil/air cooler to maintain temperature for continuous operation

Optional cover insulator for applications that may eject hazard particles such as wood shredding.

Control Panel

Standalone electrical control panel with Siemens PLC control system and Schneider electrical components.

Manual and automatic controls for rotor direction and hydraulic force feeding device

Intelligent programming whereby the motor automatically reverses on overload and stops when the machine is idle

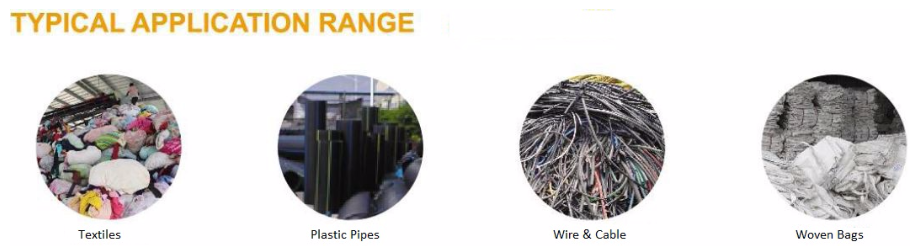

Applications

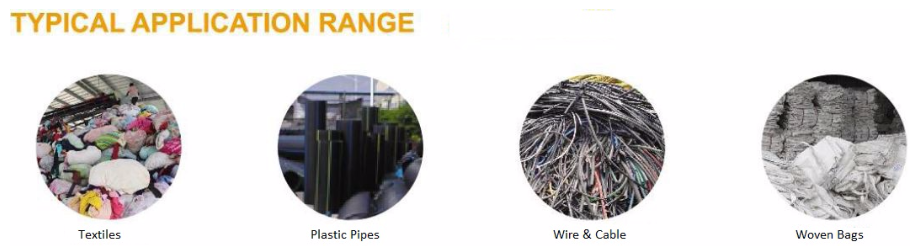

· Plastics

Mouldings, Purgings/Lump, Profiles, Films etc.

· Timber/Wood

Pallets, Joiners Waste, Green Waste etc.

· Paper & Cardboard

Confidential Documents, Production Waste, Packaging Materials etc.

· Copper Cable

Household, Telecoms and Industrial Cables including S.W.A

· Aluminum

Used Beverage Cans (UBC's), Swarf, Cables etc.

· Textiles

Carpet (Rolls & Tiles), Garments etc.

· Security Destruction

Counterfeit Items, Faulty Goods, Out of Date Stock etc.