- Portada

- Solución del sistema

- Línea de producción de trituración y reciclaje de martillos

- Línea de producción de prensado de tortas de virutas de metal

- Línea de producción de reciclaje de alambre

- Soluciones de recuperación de filtros de aceite

- Línea de reciclaje de radiadores residuales

- Línea de Lavado y Peletizado de Películas Plásticas

- Solución de trituración de aluminio fundido

- Soluciones de reciclaje de chatarra

- Clasificadora de inteligencia artificial para botellas de plástico

- Trituradoras de basura

- Sorting Machine

- Empacadora de residuos

- Scrap Metal Baler

- Vertical Baler

- Horizontal Baler

- Noticias de la empresa

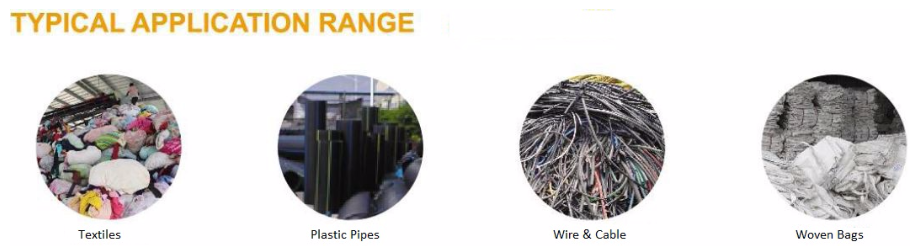

- Recycling Machine

- Product Center

- Acerca de ENERPAT

- Contáctenos